The Controversial Bet on Deep Sea Mining to Meet Surging EV Battery Demand

The promise of clean transportation is colliding with the risks of deep-sea mining, raising difficult questions about what we’re willing to sacrifice for electric cars.

The hum of an electric vehicle gliding past Nairobi’s matatus and motorbikes feels like a glimpse into the future: cleaner air, quieter streets, fewer tailpipes belching smoke. But under that promise lies a hidden struggle — the scramble to secure the metals that power the batteries inside those sleek machines.

For years, the electric vehicle supply chain leaned heavily on terrestrial mining, particularly for nickel, cobalt, and manganese. Indonesia’s vast nickel reserves, Congo’s cobalt mines, and copper from South America have long underpinned the shift away from fossil fuels. Now, though, the ground is shifting — literally. Ore grades are falling. Extraction is becoming costlier, dirtier, and more politically fraught. Automakers, eager to keep their “green” credentials intact, are turning their gaze from scarred landscapes to the unlit depths of the ocean.

The Allure Of Polymetallic Nodules

Thousands of meters below the surface of the Pacific, potato-sized rocks litter the seafloor in a vast region known as the Clarion-Clipperton Zone. These polymetallic nodules are unlike traditional ore deposits. Each one contains a geological cocktail of nickel, cobalt, manganese, and copper — the precise metals needed for lithium-ion batteries.

The appeal is obvious. Land mines typically yield one dominant metal, leaving companies to chase multiple supply chains across continents. Nodules, by contrast, bundle them all together. Mining advocates describe them as “batteries in rock form,” a jackpot of resources that could, in theory, reduce the industry’s environmental footprint compared to ripping up forests or blasting mountainsides.

Companies like The Metals Company (TMC), working under sponsorship from the tiny Pacific nation of Nauru, are making the case that harvesting nodules could deliver high concentrations of battery metals at scale, with fewer of the human rights scandals and carbon costs tied to terrestrial mining. For automakers under mounting pressure to prove their products are truly sustainable, it’s a compelling narrative.

Supply Chain Security Meets Ethical Sourcing

This pivot isn’t just about finding more metal. It’s about finding it reliably and responsibly. Consumers are asking tougher questions, regulators are tightening oversight, and brand reputations are on the line. Land-based mining carries baggage: deforestation in Indonesia, allegations of child labor in Congo, rivers poisoned in the Amazon.

Automakers like Tesla, Volkswagen, and General Motors face a delicate balancing act. They must expand production fast enough to meet global climate targets while proving their supply chains are clean. Deep sea mining, at least on paper, offers a buffer against land rights disputes, geopolitical flashpoints, and the reputational risks of traditional mining. In a world where supply shocks can stall entire industries, a more diversified metals pipeline has undeniable appeal.

The Unseen Cost: Ecological Disruption

Yet the promise comes shadowed by profound questions. Marine biologists warn that the deep ocean is not an empty void but a living system, home to species adapted to crushing pressure and eternal darkness. Many of these organisms have never been studied. Some may hold unknown scientific or medicinal value. Vacuuming nodules from the seabed could stir up sediment plumes, burying fragile ecosystems and wiping out biodiversity before it is even documented.

Unlike terrestrial mines, whose scars are visible on the surface, the impacts of deep sea mining unfold in a world few will ever see. That makes the trade-off harder to grasp, and potentially more dangerous. Once lost, these ecosystems may take centuries — or longer — to recover, if they recover at all.

Technology At The Frontier

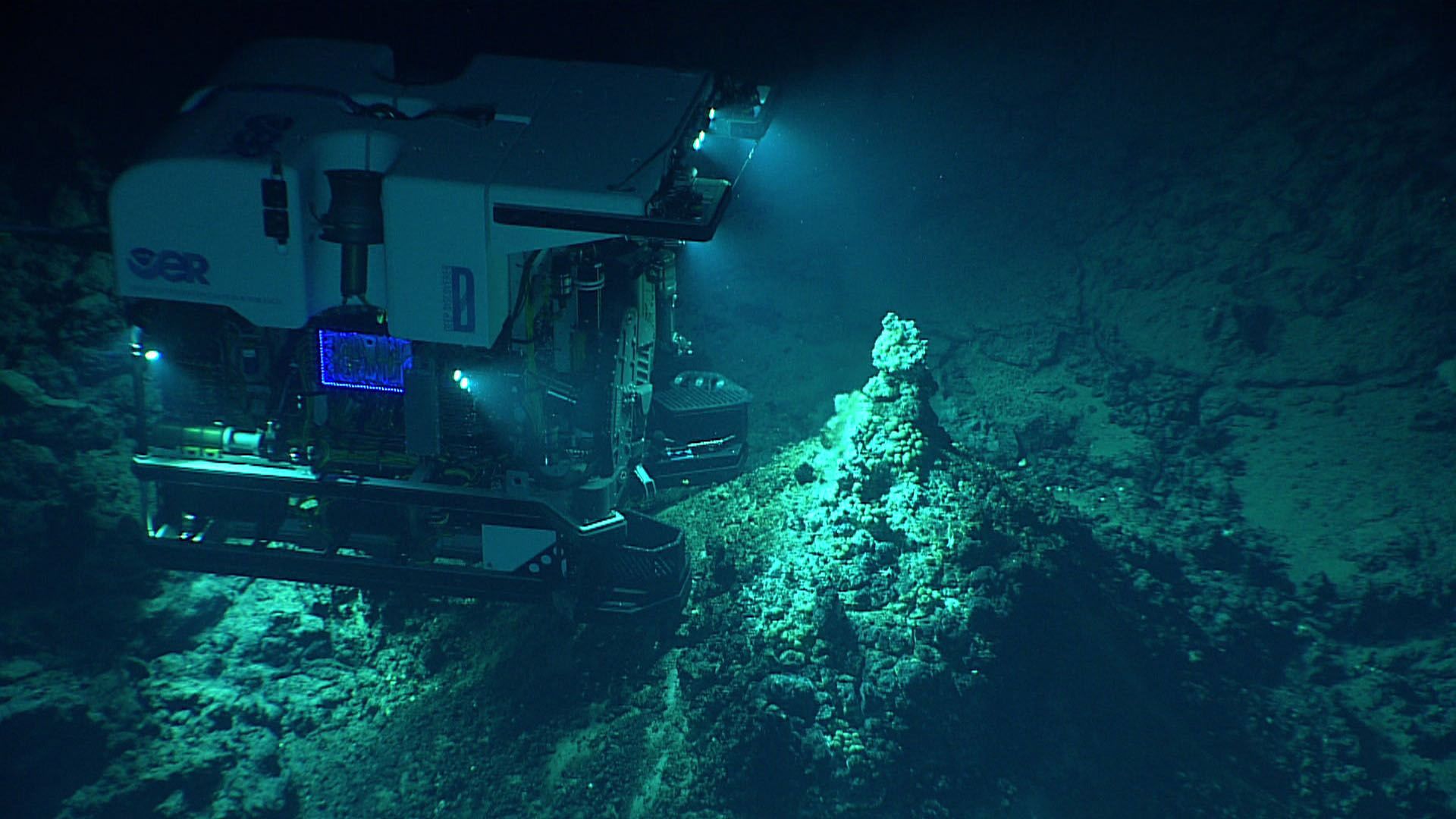

Extracting nodules isn’t a matter of sending divers down with buckets. It requires fleets of robotic collectors, remotely operated vehicles, and powerful hydraulic systems capable of operating 4,000 meters below the surface. Data from these machines must be streamed back through IoT-style sensors, satellite links, and AI-powered environmental monitors.

This turns deep sea mining into a test of technology as much as geology. The tools are still experimental, the costs still daunting. Whether commercial-scale operations can deliver on promises of efficiency and environmental responsibility remains an open question.

A Decade Of Choices

The electric vehicle industry stands at a crossroads. One path leads downward — into the abyss, toward polymetallic nodules and the risks they carry. The other leans on innovation above ground: battery recycling, circular supply chains, and new chemistries that reduce dependence on metals like cobalt altogether.

What’s certain is that the story of electrification extends far beyond glossy EV showrooms. It stretches into the jungles of Indonesia, the mines of Congo, and now the abyssal plains of the Pacific. The clean energy transition is not only a race against fossil fuels — it’s a contest over where we’re willing to dig, dredge, or dive to keep the promise of a greener future alive.

Go to TECHTRENDSKE.co.ke for more tech and business news from the African continent.

Mark your calendars! The TechTrends Pulse is back in Nairobi this October. Join innovators, business leaders, policymakers & tech partners for a half-day forum as we explore how AI is transforming industries, driving digital inclusion, and shaping the future of work in Kenya. Limited slots – Register now – here.

Follow us on WhatsApp, Telegram, Twitter, and Facebook, or subscribe to our weekly newsletter to ensure you don’t miss out on any future updates. Send tips to editorial@techtrendsmedia.co.ke